As the lithium battery industry enters a critical phase of high-quality development, how can you truly gauge a company's technical prowess and commitment to service? How can you identify solutions that will enhance your production efficiency and reduce costs? Today, Hangke Technology proudly unveils its Sixth Factory Showroom—not merely a display of equipment, but a comprehensive value experience space designed with customer success at its core.

Step Inside Hangke: From Heritage to Global Vision

At the heart of the showroom, you’ll discover:Leadership & Culture: The vision of Ji Cao, CEO of Hangke Technology, and our core values—Quality, Reliability, Pragmatism, and Innovation—drive our mission to become a $1 billion benchmark in the spirit of ASML.Global Trust: Choosing Hangke means partnering with a team that understands your challenges and delivers solutions tailored to your needs.

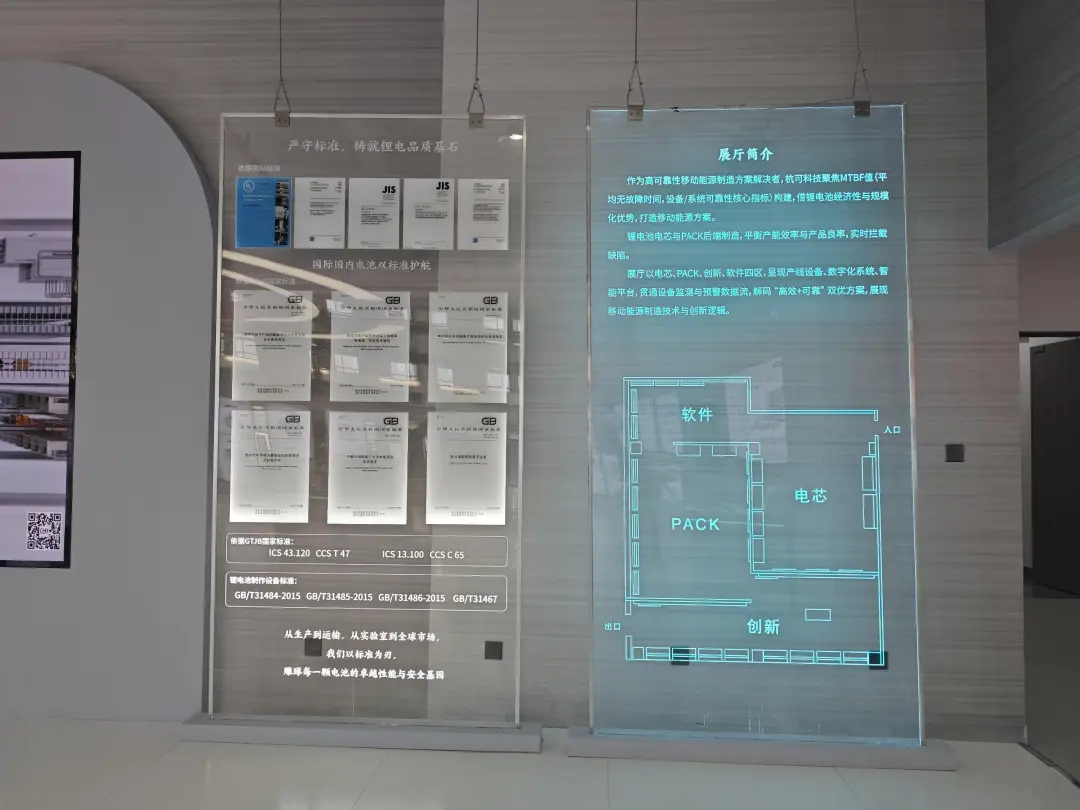

Four Themed Zones: Every Detail Designed for Customer Value

Cell Zone: Quality Starts Here

From consumer electronics to EV and large-scale energy storage, cell performance defines end-product value. Our solutions include:Full-range testing systems (0.1A–1000A) for all battery types.90%+ in-house core components for faster customization and delivery.4th-gen formation equipment saving ¥3M+/GWh annually with 52 safety protocols for zero fire incidents.

Software Zone: Predictive Intelligence - Transforming Production Management from Reactive to Proactive

What plagues us most about the production lines ?Unexpected failures and hidden defects. Hangke's Comprehensive Reliability Prediction System for lithium battery production lines is designed precisely to address these challenges:

Our Battery Defect Detection Module utilizes millisecond-level monitoring and AI algorithms to accurately identify charge-discharge abnormalities, significantly reducing quality losses.

The PHM (Prognostics and Health Management) System predicts equipment failures in advance, reducing downtime by 30% and ensuring more controllable production schedules.

By replacing experience-based judgments with data-driven decision making, we help you resolve issues before they occur.

PACK Zone: Flexible Production + Full-process Control for Multi-scenario Applications

The PACK process is where battery performance becomes reality. Here, we've considered every step for you from incoming cell inspection to module assembly, and from flexible production line design to complete data traceability.

Key features include:

6-axis robotic automation that minimizes human error and enhances module consistency.

Flexible line designs that quickly adapt to different order requirements without major retrofitting.

Proprietary power cabinets that precisely capture test data, ensuring every PACK meets end-product standards.

Whether for automotive, energy storage, or consumer electronics, we make PACK production both efficient and reliable.

Innovation Zone: Securing Future Opportunities - Sharing Industry Advancements

As small prismatic batteries and solid-state batteries emerge as game-changers, Hangke has already developed cutting-edge solutions:

Small Steel-Shell Battery Formation & Grading Systems with precise temperature and current control ensure high safety standards, helping clients capitalize on the digital battery market boom.

Solid-State Battery Formation & Grading Systems accommodate multiple electrolyte processes, solving time-consuming workflow challenges and paving the way for next-gen technology adoption.

We're not just meeting today’s needs - we’re partnering with you to seize 5-10 years of future industry opportunities.

Beyond Display: Full Lifecycle Partnership Empowerment

This showroom's value extends far beyond "seeing." From initial plant planning and production line design, through equipment integration and software deployment, to ongoing maintenance support and technological upgrades - Hangke's Full Lifecycle Service philosophy builds competitive advantages through four core capabilities: Design Foundations, Integration Empowerment, Digital Twin Implementation, Intelligent Upgrades.

Hangke Technology's Sixth Factory Showroom is more than a window - it's a bridge. It connects 40 years of Hangke's technical expertise with actual customer needs with current production pain points with future industry opportunities.

We cordially invite you to visit the Hangke Technology’s Sixth Factory Showroom and witness firsthand how to make lithium battery production more efficient, safer, and more competitive. Here, every technology and every piece of equipment serves one singular purpose: to collaborate with you in creating a high-quality future for the green energy industry.

Address: No. 89, Gaoxin 13th Road, Xiaoshan District, Hangzhou, China

Finally, our heartfelt thanks to all members of the Showroom project team - your efforts has made this showroom shine!